Soutien

- Vidéos

- Documentation

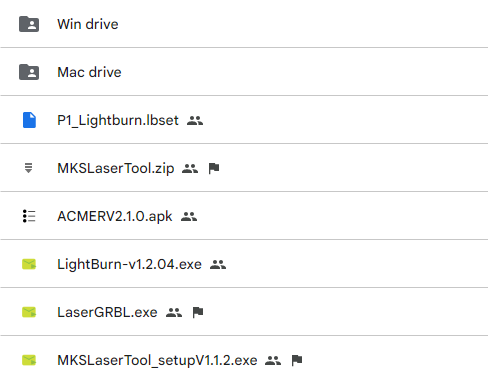

- Logiciel

- Conducteurs

- Micrologiciel

- Données de la carte TF

- Réglage du matériau

Manuel d'instructions ACMER P1

Manuel d'utilisation de l'ACMER P1 Lightburn

ACMER P1 LaserGRBL Manuel d'utilisation

Manuel d'utilisation de l'application ACMER P1

Actualisation du micrologiciel de la carte mère ACMER P1

WIFI Mode

SSID: ACMER-P1-XXXXX

Mot de passe: 12345678

Liste des logiciels compatibles avec ACMER P1

LightBurn : Windows / macOS / Linux – Essai gratuit de 30 jours

Tips: MKS TOOL is a tool that allows you to quickly modify the display UI and configuration files using a graphical interface

ACMER P1 Firmware V1.1_2023082801

This firmware is compatible with ACMER P1 10W and ACMER P1 Pro 20W.

Upgrading the firmware may bring the following benefits: fixing vulnerabilities and errors, improving performance and compatibility.

Please update as needed.

Settings Guide

The most common question in forums, especially on Facebook, is "What settings do I need for my project?" However, it's important to note that only you can answer that question. Each person has unique requirements and expectations for their desired result—whether it's brighter or darker. Additionally, every material and laser machine varies, even within the same batch. It's not uncommon to find discrepancies in performance, where one piece of plywood may work perfectly while another from the same package doesn't. These variations occur due to the nature of natural materials and differences in processing. Therefore, there are no universal settings that guarantee consistent results.

Speed and Performance Relationship

The speed at which the laser moves affects its performance. The more concentrated the power is on a point, the more material gets burned. This depends on the energy used per unit of time and area. When the laser moves faster, less energy is distributed over the same area per unit of time, resulting in proportional settings. For example, achieving 80% performance at 1000 mm/min should give a similar result as 40% performance at 500 mm/min. However, this guideline is not entirely accurate due to non-linear material reactions to energy.

When increasing speed reaches its limit, additional power won't compensate for it. In such cases, increasing the number of passes is necessary. This means the laser will go over each spot multiple times, resulting in deeper cuts or engravings.

- P1 10w

- P1 20w

Engraving Parameters

Material

Power(%)

Speed(mm/min)

leather

100

4500

Basswood

55

4800

Leather

15

6000

Ceramic

50

6000

Kraft paper

40

7000

Acrylic

100

4000

Stainless steel

100

300

Cutting Parameters

Material

Thickness

Power(%)

Speed(mm/min)

Acrylic

2mm

100

150

Acrylic

4mm

100

100

Basswood

2mm

100

360

Basswood

6mm

100

150

Basswood

7.5mm

100

120

Kraft paper

1mm

100

1500

Leather

1mm

100

1500

Engraving Parameters

Material

Power(%)

Speed(mm/min)

leather

15

Basswood

20

3000

aluminumsheet

80

2000

Ceramic

30

3000

Kraft paper

10

3000

Acrylic

30

2000

Stainless steel

100

2000

Cutting Parameters

Material

Thickness

Power(%)

Speed(mm/min)

Acrylic

30mm

100

100

Acrylic

4mm

100

300

Basswood

2mm

100

700

Basswood

4mm

100

350

Basswood

5mm

100

300

Basswood

8mm

100

120

Basswood

20mm

100

500

- Videos

- Documentation

- Software

- Drivers

- Firmware

- TF Card Data

- Material Setting

ACMER P2 Instruction Manual

ACMER P2 Lightburn User Manual

ACMER P2 LaserGRBL User Manual

ACMER P2 FAQ

ACMER P2 Firmware Update Intructions

WIFI Mode

SSID: ACMER-P2-XXXXX

Password: 12345678

List of compatible software with ACMER P2

- LaserGrbl: Free Software, Please user 4.9.4 or higher

- LightBurn: Windows / macOS / Linux – 30 Day Free Trial

Tips: MKS TOOL is a tool that allows you to quickly modify the display UI and configuration files using a graphical interface

ACMER P2 Firmware V1.1_20230317

This firmware is compatible with ACMER P1 10W and ACMER P1 Pro 20W.

Upgrading the firmware may bring the following benefits: fixing vulnerabilities and errors, improving performance and compatibility.

Please update as needed.

Settings Guide

The most common question in forums, especially on Facebook, is "What settings do I need for my project?" However, it's important to note that only you can answer that question. Each person has unique requirements and expectations for their desired result—whether it's brighter or darker. Additionally, every material and laser machine varies, even within the same batch. It's not uncommon to find discrepancies in performance, where one piece of plywood may work perfectly while another from the same package doesn't. These variations occur due to the nature of natural materials and differences in processing. Therefore, there are no universal settings that guarantee consistent results.

Speed and Performance Relationship

The speed at which the laser moves affects its performance. The more concentrated the power is on a point, the more material gets burned. This depends on the energy used per unit of time and area. When the laser moves faster, less energy is distributed over the same area per unit of time, resulting in proportional settings. For example, achieving 80% performance at 1000 mm/min should give a similar result as 40% performance at 500 mm/min. However, this guideline is not entirely accurate due to non-linear material reactions to energy.

When increasing speed reaches its limit, additional power won't compensate for it. In such cases, increasing the number of passes is necessary. This means the laser will go over each spot multiple times, resulting in deeper cuts or engravings.

- P2 10w

- P2 20w

- P2 33w

Engraving Parameters

Material

Power(%)

Speed(mm/min)

Basswood

100

8000

Leather

80

20000

Kraft paper

85

15000

MDF

85

15000

Stainless steel

100

800

Anodizedaluminum

100

6000

Glass

100

10000

Ceramic

100

10000

Acrylic

100

20000

Cutting Parameters

Material

Thickness

Power(%)

Speed(mm/min)

Basswood

4mm

100

200

Basswood

6mm

100

120

Basswood

8mm

100

150

Basswood

10mm

100

150

Cork Wood

10mm

100

100

Leather

1mm

100

1500

Kraft paper

1mm

100

1500

MDF

2mm

100

200

MDF

3mm

100

180

Acrylic

2mm

100

150

Acrylic

4mm

100

150

Engraving Parameters

Material

Power(%)

Speed(mm/min)

Basswood

80

20000

Leather

50

20000

Kraft paper

85

20000

MDF

70

20000

Stainless steel

100

2000

Anodizedaluminum

100

10000

Glass

100

20000

Ceramic

100

20000

Acrylic

60

20000

Cutting Parameters

Material

Thickness

Power(%)

Speed(mm/min)

Basswood

4mm

100

400

Basswood

6mm

100

300

Basswood

8mm

100

200

Basswood

10mm

100

150

Cork Wood

10mm

100

100

Leather

1mm

100

3000

Kraft paper

1mm

100

3000

MDF

2mm

100

500

MDF

3mm

100

400

Acrylic

2mm

100

300

Acrylic

4mm

100

200

Engraving Parameters

Material

Power(%)

Speed(mm/min)

Basswood

65

20000

Leather

40

20000

Kraft paper

35

20000

MDF

20000

Stainless steel

100

3000

Anodizedaluminum

100

15000

Glass

70

20000

Ceramic

70

20000

Acrylic

40

20000

Cutting Parameters

Material

Thickness

Power(%)

Speed(mm/min)

Basswood

4mm

100

600

Basswood

6mm

100

400

Basswood

8mm

100

300

Basswood

10mm

100

200

Basswood

12mm

100

100

Cork Wood

10mm

100

Leather

1mm

100

4500

Kraft paper

1mm

100

4500

MDF

2mm

100

MDF

3mm

100

700

Acrylic

2mm

100

500

Acrylic

4mm

100

400

- Videos

- Documentation

- Software

- Drivers

- Firmware

- TF Card Data

ACMER P1 S Pro Instruction Manual

ACMER P1 S Pro Lightburn User Manual

ACMER P1 S Pro LaserGRBL User Manual

ACMER P1 S Pro FAQ

ACMER P1 S Pro Firmware Update Intructions

WIFI Mode

SSID: ACMER-P1-XXXXX

Password: 12345678

List of compatible software with ACMER P1 S Pro

- LaserGrbl: Free Software, Please user 4.9.4 or higher

- LightBurn: Windows / macOS / Linux – 30 Day Free Trial

Tips: MKS TOOL is a tool that allows you to quickly modify the display UI and configuration files using a graphical interface

ACMER_P1_SPRO_Firmware_V1.0_20231109

This firmware is compatible with ACMER P1 10W and ACMER P1 Pro 20W.

Upgrading the firmware may bring the following benefits: fixing vulnerabilities and errors, improving performance and compatibility.

Please update as needed.